VACUUM TUBE FURNACES

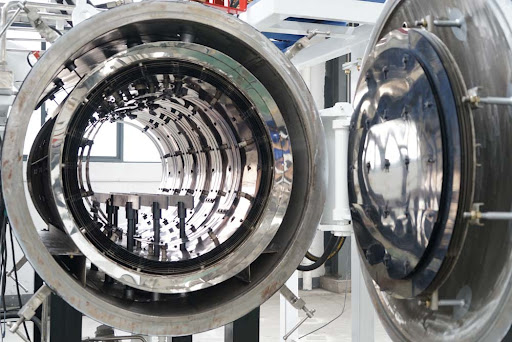

A vacuum tube furnace is an advanced thermal processing system designed to heat materials in a vacuum environment. This setup minimizes the presence of gases and contaminants, allowing for high-purity treatments of metals, ceramics, and other materials. The furnace typically consists of a cylindrical tube that can reach high temperatures, often exceeding 1,500°C, while maintaining a controlled vacuum or inert atmosphere.

The vacuum environment is crucial for applications such as sintering, annealing, and chemical vapor deposition, where even trace amounts of oxygen or other reactive gases can adversely affect material properties. By eliminating these impurities, vacuum tube furnaces enable the production of high-quality materials with enhanced performance characteristics.

Additionally, these furnaces are equipped with precise temperature control and monitoring systems, ensuring consistent and reproducible results. As a result, vacuum tube furnaces are widely used in research, materials science, and semiconductor manufacturing, making them essential tools for developing cutting-edge technologies.

.png)