Vacuum Diffusion Welding

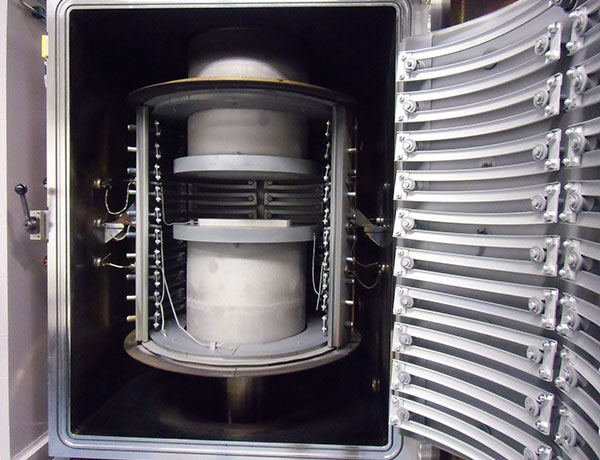

Vacuum diffusion welding furnace is a solid state welding process, in which the surface to be welded is subjected to a vacuum environment, a certain temperature range, and pressure to achieve relatively rapid atomic diffusion, thereby achieving metallurgical bonding.

The characteristic of vacuum diffusion welding furnace:

The characteristics of vacuum diffusion welding furnace for conventional structural products are introduced from two aspects: advantages and disadvantages. In the actual engineering application process, the advantages and disadvantages of products with different structures will have new content.

Advantages:

- Compared to fusion welding and brazing, the chemical composition and microstructure of the joint are more uniform;

- The joint strength is higher, and some metal vacuum diffusion welds are close to or reach the strength of the base material;

- There are many types of weldable materials;

- The welding temperature is relatively low, which has a relatively small impact on the properties of the base material;

- Suitable for surface welding;

- Compared with brazing, vacuum diffusion welding furnace belongs to "no excess material" welding without brazing material.

Disadvantages:

- The precision, cleanliness, and assembly requirements for the surface processing of materials to be welded are extremely strict;

- The one-time investment in equipment is relatively large, and the size of welding parts is limited by the specifications of the equipment vacuum chamber;

- Some materials have a higher threshold for technological advancement, which places higher demands on process technicians and operators;

- At present, there is a lack of effective non-destructive testing methods, and ultrasound C-scan can only be used as a reference method.

.png)