VACUUM SINTERING FURNACE

Vacuum sintering is one of the unsung heroes of industrial metallurgy. In this crucial process, materials are heated in a vacuum environment until they are almost at the point of melting. As heat is applied, the materials become compacted, creating new materials with completely different properties. Vacuum sintering is a heat treatment used to join parts with the least waste to produce consistent components without seams, fillers or joints. The components treated using a vacuum sintering furnace is often intricate, delicate and tricky to make like the manufacturing of ceramics, metal components, and certain types of composite materials.

1.High Temperature Vacuum Sintering Furnace

- Purpose: Used in powder metallurgy and sintering of magnetic materials.

- Protective Atmosphere: Reduces oxidation during charging for high-quality output.

- Automation: Controlled by PLC and temperature controller for precision.

- Temperature Range: Available at 1300°C, 1450°C, 1600°C, 1800°C, and above.

Main Components:

- 1300°C Sintering Furnace: Primarily for magnetic materials and vacuum sintering in powder metallurgy, with an optional glove box.

- Mobile Glove Box System: Connects to multiple furnaces, saving space and cost.

- Silicon Carbide Sintering Furnace: For silicon carbide reaction sintering at up to 1800°C.

- Vacuum Degreasing & Sintering Furnace: Prepares various alloys in a multi-chamber system, enhancing consistency.

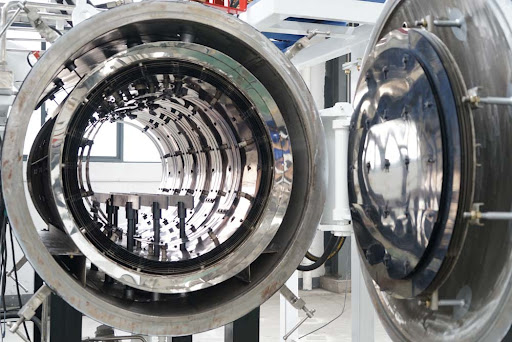

2. Double Chamber Vacuum Sintering Furnace

- Overview: Advanced high-temperature furnace for metals and ceramics.

- Operation: Uses vacuum pressure for high-temp compaction, creating a sealed atmosphere.

- Features: Enhanced heating, ideal for intricate, high-temperature material processing.

.png)